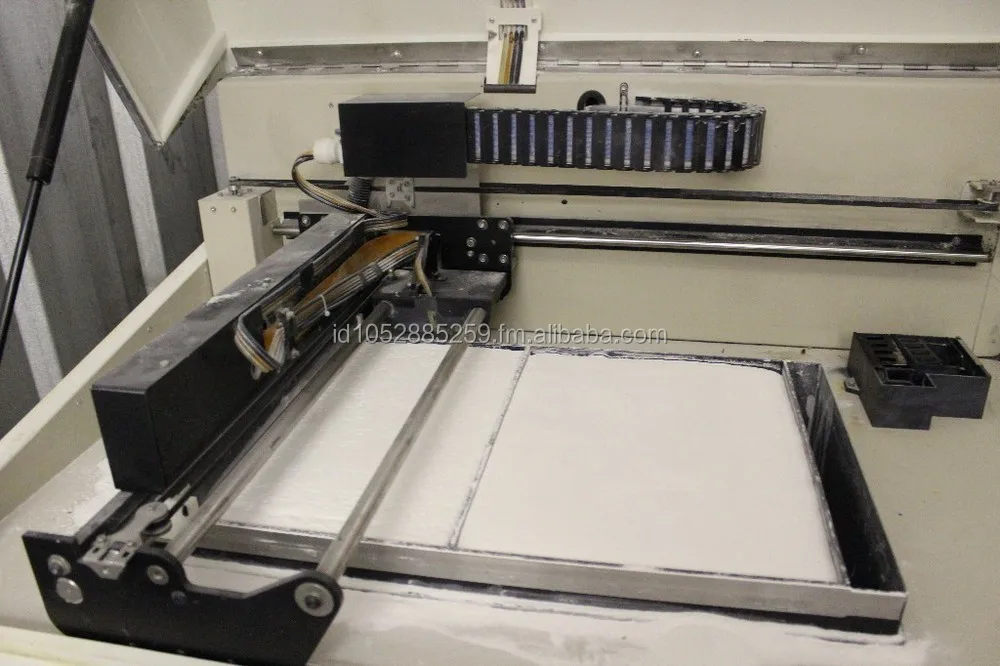

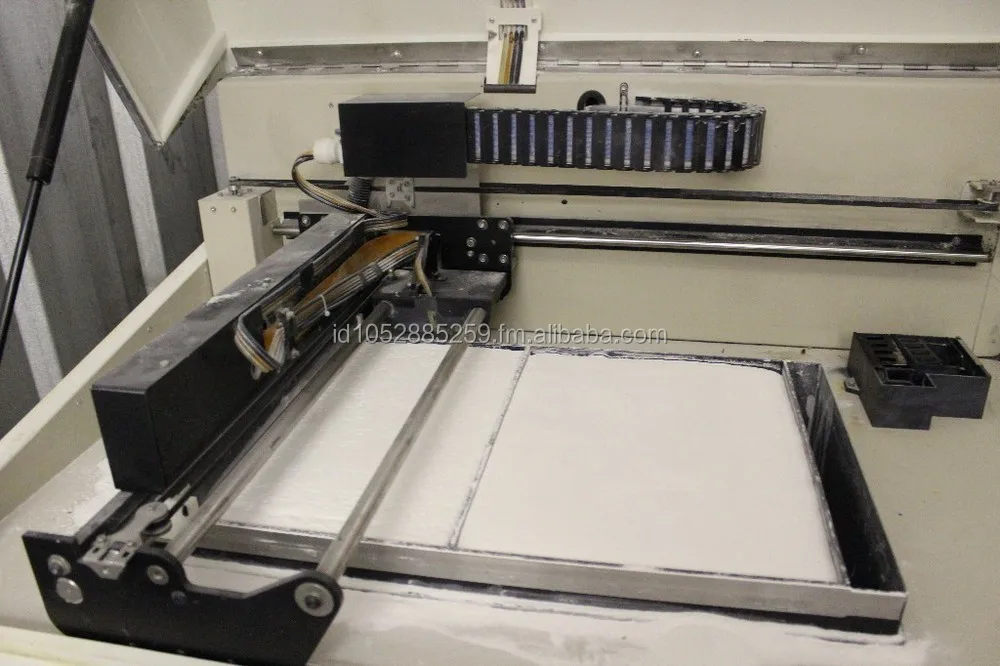

Take a look at the 2D mode in order to check if the material distribution is like you expect it to be. Try to foresee the difficulties that may arise in the removal process as the printed parts can be very fragile. Move, scale and rotate the model as you want in order to optimize the printing process. The STL file should be a proper closed volume model with coherent normals. Open your STL file, select the units for your model, and the powder type (ZP150). Put the machine on-line pressing the 'Online' button. Check that the printing bed is prepared to print. Check the cleaning tank levels at the centre bottom part of the machine: the left one (cleaning liquid) should be almost full and the right one (residual liquid) should be empty or almost empty. Close the caps softly, don't apply pressure. Don't fill them too much since the binder ages in the tank. Fill all four tanks with binder at least over the binder extraction pipes at the back side of the tanks. zp150 white, high resolution printing powder.

Exporting single objects in every STL-file is recommended for better nesting in multiple-object prints.Coherent normal direction for all the closed volumes (normals pointing outside).

Check 3D model validity before printing!.Models can be generated by every software capable of exporting STL files.Color 3D Printer: mostly used in monochrome mode.Printable volume: 250mm, 350mm, 200mm (width, depth, height).

0 kommentar(er)

0 kommentar(er)